Bridge near Doroslovo

The bridge is built in 1965. The bridge design project does not exist. It is designed and built as a frame – intrados type of structure, as an open-box „?“ shape section consisting of two walls variable in height (along the parabolic line of intrados within the main span and linear along the side spans). The walls are connected with the concrete deck and transverse girders. A detailed record of the bridge's geometrical and material characteristics is carried out. At the same time, a detailed visual inspection of the bridge structure is carried out to identify and locate all eventual observed damage. As an outcome, the bridge documentation of the bridge „as it is now“ is completed as a base ground for the bridge FEM numerical static analysis for the three cases of live loads: (1) according to the code valid at the time when the bridge is constructed; (2) according to the code valid at the moment; and (3) according to the performed limit state control of the bridge critical section bearing capacity (moment of fracture). Since the bridge structure satisfies the criterion (1) and (2), but the limit state analysis of the critical sections does not have the needed safety coefficient, a decision was made that the real bridge load-bearing capacity may be determined only by applying the proof load testing. The mentioned testing will follow soon.

Pile dynamic load testing (Serbia)

Construction of viaduct “Cortanovci” on the railway line Belgrade-Budapest. The pile dynamic load bearing capacity testing is carried out on the two drilled piles 1.20 m in diameter and 30.00 m deep. The pile is stricken by the free-falling impact load of 10 t, falling from the height of 0.50, 1.00, 1.50 and 2.00 m. Testing is carried out in accordance with standard ASTM D 4945 – 08.

Testing of existing bridge over channel near Sivac (Serbia)

Project of the local road construction Sivac-Stapar

Load testing of the bridge over channel near Sivac and load bearing capacity assessment,

Central Road Laboratory (CPL), Novi Sad, Serbia

Head of Structure Testing Department

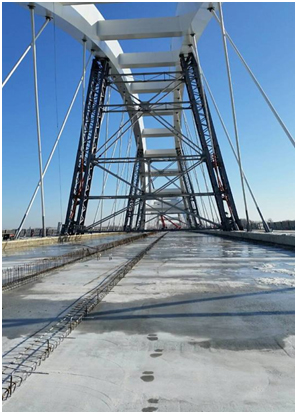

Construction of „Zezelj’s bridge“over Danubein Novi Sad (Serbia)

DB Engineering & Consulting GmbH

Branch Office Belgrade

Professional supervision,

Key Expert for Materials

Bridge load testing onHighway E-75 Belgrade-Nis-border with BJR Macedonia

Section:

Srpska Kuća – Levosoje,

Central Road Laboratory (CPL), Novi Sad, Serbia

Head of Structure Testing Department

Road Rehabilitation and Safety Project

Road Rehabilitation and Safety Project, Emergency works component on the urgent maintenance and reparation on some sections of the state roads of Repablic of Serbia, Consulting service and supervision of work on the bridges (JV “NIEVELT – CPL”)

Load testing of bridges on the Highway E-736 Belgrade South Adriatic

Load testing of bridges on the Highway E-736 Belgrade South Adriatic, Head of the testing team (CPL, Novi Sad – 2015)

Load Testing of the Bridge over river Liakhvi in Gori, Georgia

( JV Nievelt Engenieur GmbH, Vienna, Austria, VCE Consult ZT-GmbH, Vienna, Austria; Centralna Putna Laboratorija (CPL), Novi Sad, Serbia)

Works on bridges of highway E-60, Georgia

Supervision of construction work on bridges of highway E-60, Section Tbilsi - Gori, Georgia (Nievelt Ingenieur GmbH, Austria)

Works on Gazela bridge over river Sava in Belgrade

Supervision of reparation works on Gazela bridge over river Sava in Belgrade – work in progress (Assistant Resident Engineer for the Bridge)

Bridge over river Sava near Obrenovac:

Testing of steel truss bridge structure during construction The bridge structure is designed for heating pipeline and road traffic as well. The main bridge structure over river consists of 5 independent spans. The structures K1, K2, K5 and K6 are steel one-storey truss simple beams with the span of 50 m, and the structures K3 and K4 are three-storey trusses mutually connected in continuous girder with the spans 100+140 m. Construction work and the bridge testing during erection is in progress. Load testing of the bridge is successfully carried out on 25-27, November, 2011. (Institute "Kirilo Savic", Belgrade)